Trevan Ford, Lismore, NSW, Australia 1910-2010

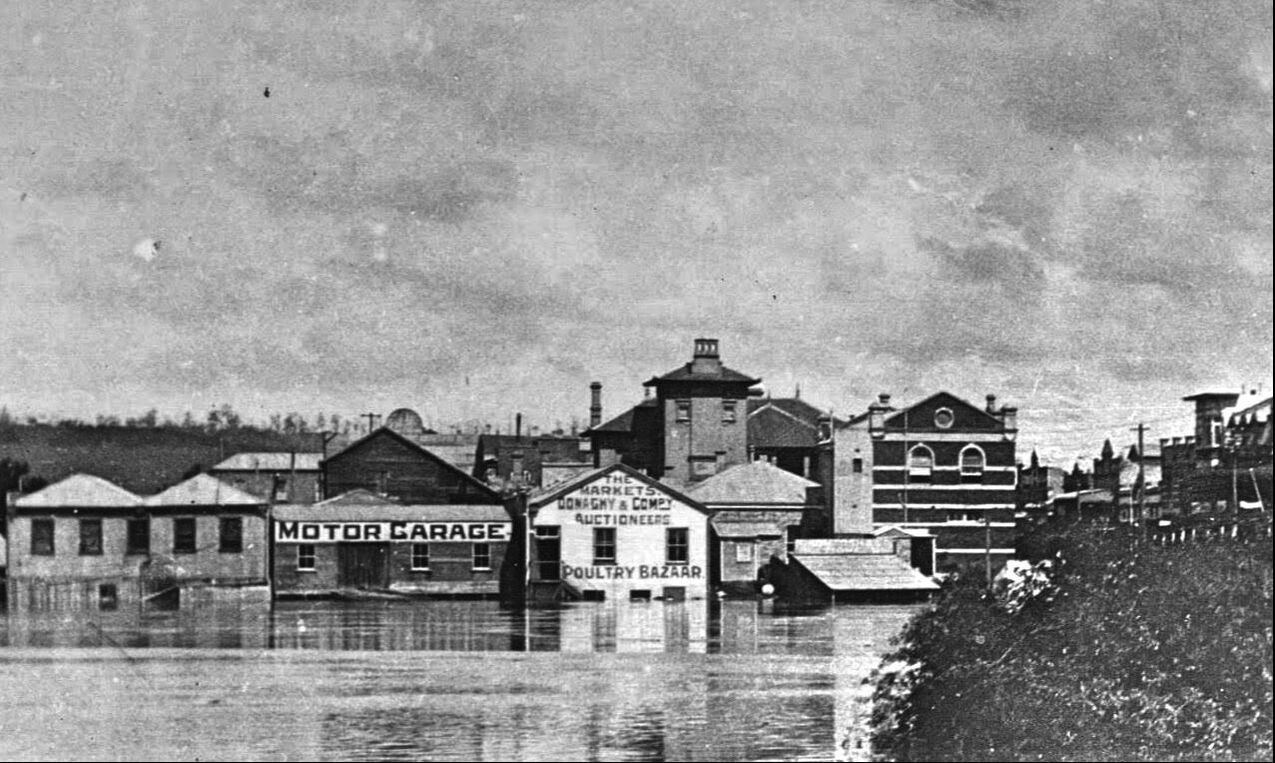

The Beginning Photo: First Trevan Garage 1910-1912

From the time RH Trevan (RH) and Stan Harrison arrived in Lismore in late 1910 with their Ford Laundlette, it was all go in the taxi hire business. In RH’s words, “we raised more dust in a week going around the block than the town had seen in its lifetime. We generally made a nuisance of ourselves and should have been run in. But we made ‘good money’, a bob [slang for one shilling/10¢] a trip while we lasted.

In 1910, Lismore’s population was approximately three thousand, with one garage servicing five motor buggies, eight motorcars and two motorbikes. RH felt the time was right to also get into the motor repair business. He proceeded to rent from agents, Macgregor Dunn, the rear portion of a building overlooking the river at the northern end of Molesworth Street, next to the original Northern Star office.

The business commenced trading as RH Trevan Motor Engineers and it could be said RH made his first motorcar sale by accident. This came about from a fire that burnt local architect, Colonel Board’s motor buggy to the ground after RH had been doing some servicing on it. Even though the Colonel was upset with his loss, he requested RH to get him one of those new fangled Model T Fords. This car came through the NSW vehicle importer and distributors, Davies & Fehon, who had recently opened a branch in Lismore to service the northern end of NSW. Prior to Davies & Fehon’s arrival in Lismore, RH had previously worked with them for a short period in Sydney, to learn more about motorcars.

At the age of twenty-six, RH’s philosophy was, ‘If you’re stationary, you’re going backwards.’ So, to make the next advancement with the business, he brought in a partner to help with financing and expansion. With Jeremiah Mahoney as a partner, they began trading as Trevan & Mahoney from an old horse stable situated down a lane, now a walkway, on the northern side of Woodlark Street, beside Browns Creek and now covered in as a car park.

It was not the best of buildings but, in RH’s words, it did have one redeeming feature, ”At the end of the day it was fashionable to sweep all the leftover rubbish straight out the back into Brown’s Creek.”

A legacy of Trevans’ Molesworth Street garage remained with this building long after RH had moved on. It was said a large hole in the roof was caused when leaking gas from an acetylene-welding bottle was ignited by the building’s exposed gas flame lighting system.

Many advertisements in the papers of 1912 stated that Trevan & Mahoney were now the oldest established motor engineers in Lismore. The enterprise had made great strides in such a short time and was capable of doing the work of gear cutting, case hardening and welding. They also advertised as agents for Overland cars and Barnet glass tyres. As for vehicle sales, they generally procured the selected type of vehicle for the client from distributors in Sydney. But in most cases it was generally the Model T Ford, which came by boat from the importers, Davies & Fehon. One of the firm’s truck sales was a big Fiat to the Nimbin firm of Northern Dairy Co-Op, the forerunner to Norco Co-Op, in 1912.

RH was responsible for many firsts in Lismore. One of these accomplishments was the installation of an engine from Mr Wicks’ old motor buggy, to drive a generator in his jewellery store in Woodlark Street. It was the first store in Lismore to have electric lighting and it was said the generator had enough current to also supply electricity through overhead wires to Somerville’s Butcher Shop on the northern side of Woodlark Street. Another innovation many people benefited from came about by RH replacing the local Diggers Theatre’s two-cylinder engine with a smoother running three-cylinder one, to help ease the flickering of the films.

RH’s installation of Lismore’s first petrol bowser got off to an eventful start when it was found that the one hundred cases, or 450 litres, of fuel that had been tipped down the filling hole, had soaked into the surrounding soil, because of the filler pipe being incorrectly connected to the tank.

In 1913, Trevan & Mahoney registered a new Studebaker Tourer as a hire car. This was not only a better form of transportation than Lismore’s many horse drawn cabs but it also allowed people to say that they had actually ridden in a car, still a novelty at the time.

In the same year, RH employed Cecil Partridge as a mechanic. Cecil stayed with the Lismore firm until he was transferred to the Murwillumbah branch in 1919, remaining there until leaving to start the Partridge and Walker Garage in Murwillumbah, in the late thirties.

Davies & Fehon, the NSW Ford vehicle distributors, closed their outlet in Lismore in late 1913 and the Josh Hewitson Motor Garage in Keen Street purchased all of Davies & Fehon Ford parts, together with tools, two new floor stock Model Ts and the Ford selling rights in the area. It possibly could be said that this move by Davies & Fehon further aggravated the poor relationship that had built up between RH and the distributor.

It is recorded that RH contacted Ford in Detroit regarding directly importing the Model Ts. He was advised that he would have to deal with Ford Canada, as they were now the world export plant for right-hand drive cars. Apparently an agreement was made between them to bypass Davies & Fehon with his stock orders. The 1923 section of the Ford Motor Company’s archives contains a letter explaining the reasons behind RH’s dislike of Davies & Fehon.

Davies & Fehon and Hewitson’s arrangement only lasted for eighteen months, after which Josh Hewitson took up the Dodge franchise. RH was again given the Ford sales rights to the territory, which stretched from Tweed Heads, down to near Grafton and inland to Tenterfield.

Over this 1910–1916 period, RH had established a regular clientele from his Ford sales, some of whose descendants are still trading with Trevans to this day. This clientele was to put him in a good position to go out on his own when, in 1916, the partnership of Trevan & Mahoney suddenly dissolved at the local racecourse, after RH found to his disgust that the firm’s money was finding its way onto racehorse betting through his partner.

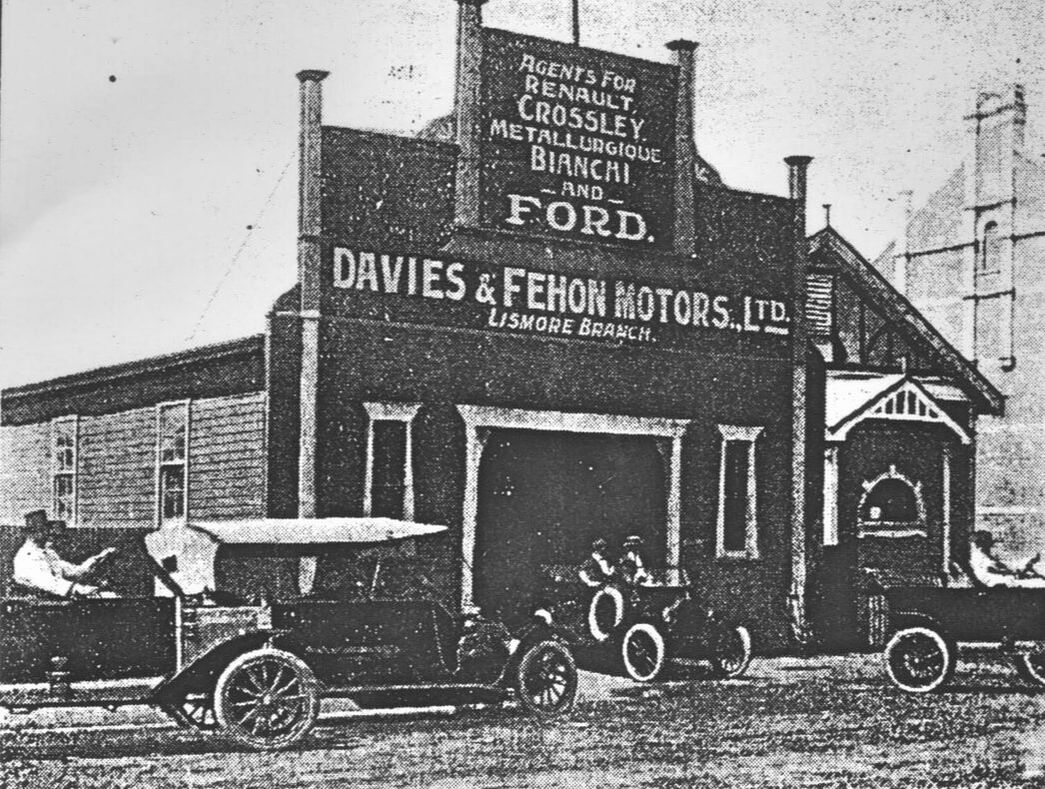

Photo below: 1911-1913, Davies & Fehon Motors, (Lismore branch) Ford Distributors in NSW.

In 1910, Lismore’s population was approximately three thousand, with one garage servicing five motor buggies, eight motorcars and two motorbikes. RH felt the time was right to also get into the motor repair business. He proceeded to rent from agents, Macgregor Dunn, the rear portion of a building overlooking the river at the northern end of Molesworth Street, next to the original Northern Star office.

The business commenced trading as RH Trevan Motor Engineers and it could be said RH made his first motorcar sale by accident. This came about from a fire that burnt local architect, Colonel Board’s motor buggy to the ground after RH had been doing some servicing on it. Even though the Colonel was upset with his loss, he requested RH to get him one of those new fangled Model T Fords. This car came through the NSW vehicle importer and distributors, Davies & Fehon, who had recently opened a branch in Lismore to service the northern end of NSW. Prior to Davies & Fehon’s arrival in Lismore, RH had previously worked with them for a short period in Sydney, to learn more about motorcars.

At the age of twenty-six, RH’s philosophy was, ‘If you’re stationary, you’re going backwards.’ So, to make the next advancement with the business, he brought in a partner to help with financing and expansion. With Jeremiah Mahoney as a partner, they began trading as Trevan & Mahoney from an old horse stable situated down a lane, now a walkway, on the northern side of Woodlark Street, beside Browns Creek and now covered in as a car park.

It was not the best of buildings but, in RH’s words, it did have one redeeming feature, ”At the end of the day it was fashionable to sweep all the leftover rubbish straight out the back into Brown’s Creek.”

A legacy of Trevans’ Molesworth Street garage remained with this building long after RH had moved on. It was said a large hole in the roof was caused when leaking gas from an acetylene-welding bottle was ignited by the building’s exposed gas flame lighting system.

Many advertisements in the papers of 1912 stated that Trevan & Mahoney were now the oldest established motor engineers in Lismore. The enterprise had made great strides in such a short time and was capable of doing the work of gear cutting, case hardening and welding. They also advertised as agents for Overland cars and Barnet glass tyres. As for vehicle sales, they generally procured the selected type of vehicle for the client from distributors in Sydney. But in most cases it was generally the Model T Ford, which came by boat from the importers, Davies & Fehon. One of the firm’s truck sales was a big Fiat to the Nimbin firm of Northern Dairy Co-Op, the forerunner to Norco Co-Op, in 1912.

RH was responsible for many firsts in Lismore. One of these accomplishments was the installation of an engine from Mr Wicks’ old motor buggy, to drive a generator in his jewellery store in Woodlark Street. It was the first store in Lismore to have electric lighting and it was said the generator had enough current to also supply electricity through overhead wires to Somerville’s Butcher Shop on the northern side of Woodlark Street. Another innovation many people benefited from came about by RH replacing the local Diggers Theatre’s two-cylinder engine with a smoother running three-cylinder one, to help ease the flickering of the films.

RH’s installation of Lismore’s first petrol bowser got off to an eventful start when it was found that the one hundred cases, or 450 litres, of fuel that had been tipped down the filling hole, had soaked into the surrounding soil, because of the filler pipe being incorrectly connected to the tank.

In 1913, Trevan & Mahoney registered a new Studebaker Tourer as a hire car. This was not only a better form of transportation than Lismore’s many horse drawn cabs but it also allowed people to say that they had actually ridden in a car, still a novelty at the time.

In the same year, RH employed Cecil Partridge as a mechanic. Cecil stayed with the Lismore firm until he was transferred to the Murwillumbah branch in 1919, remaining there until leaving to start the Partridge and Walker Garage in Murwillumbah, in the late thirties.

Davies & Fehon, the NSW Ford vehicle distributors, closed their outlet in Lismore in late 1913 and the Josh Hewitson Motor Garage in Keen Street purchased all of Davies & Fehon Ford parts, together with tools, two new floor stock Model Ts and the Ford selling rights in the area. It possibly could be said that this move by Davies & Fehon further aggravated the poor relationship that had built up between RH and the distributor.

It is recorded that RH contacted Ford in Detroit regarding directly importing the Model Ts. He was advised that he would have to deal with Ford Canada, as they were now the world export plant for right-hand drive cars. Apparently an agreement was made between them to bypass Davies & Fehon with his stock orders. The 1923 section of the Ford Motor Company’s archives contains a letter explaining the reasons behind RH’s dislike of Davies & Fehon.

Davies & Fehon and Hewitson’s arrangement only lasted for eighteen months, after which Josh Hewitson took up the Dodge franchise. RH was again given the Ford sales rights to the territory, which stretched from Tweed Heads, down to near Grafton and inland to Tenterfield.

Over this 1910–1916 period, RH had established a regular clientele from his Ford sales, some of whose descendants are still trading with Trevans to this day. This clientele was to put him in a good position to go out on his own when, in 1916, the partnership of Trevan & Mahoney suddenly dissolved at the local racecourse, after RH found to his disgust that the firm’s money was finding its way onto racehorse betting through his partner.

Photo below: 1911-1913, Davies & Fehon Motors, (Lismore branch) Ford Distributors in NSW.

A New Start -1916

With a new start, RH purchased an old skating rink building in Molesworth Street, opposite the then Council Chambers building, and began trading again as RH Trevan Motor Engineers.

The old skating rink was an ideal size and had rear access into Carrington Street. The main fault was its wooden floor which, in later years, became oil-soaked and continually needed to be patched, as vehicles or car jacks pushed holes through it. As business progressed, Joe Anderson was employed as a salesman to sell the Model T cars and trucks and later the Irish-built Fordson tractor, which was planned to be released onto the market in Australia in 1918. This tractor became an instant success with farmers but caused mechanics many headaches with its poorly designed gearbox. As RH described to Ford, “ it was a case of shovelling the gears out by the spadeful”. The later models, built in Dagenham in the United Kingdom, proved to be a far superior tractor.

With the outbreak of World War I in 1914, many a farmer and his son enlisted for overseas duty, causing most business activity to slow down until the war’s end in 1918. On return of enlisted men to the farms and industry, Australia was soon on the move again. RH’s belated plans to open a sales and service facility in the neglected Tweed Valley end of the territory were soon implemented. A section of AG Hayes’ coach building works in Prospero Street, South Murwillumbah, was rented and opened for business in 1919, and RH’s brother, Bill, who had come up from the family home in Victoria, was given the opportunity to join the business. He started in the Murwillumbah office and in 1924 took over as manager, when the then manager, Jim Cooper, was transferred to the newly opened Ballina facility.

The next company expansion came with the purchase of land in Casino for another garage outlet in 1922. In the same year, RH floated the firm into a company, RH Trevan Ltd, with shares being issued to Bill Trevan and selected staff. All land and buildings owned by RH, in person, were transferred to the new company in exchange for shares in his name.

From 1918 through to the early 1920s, business was good with sales of Model T Fords buoyant, mainly due to its low price together with the revolutionary semi-automatic transmission that enabled the car to be rocked back and forth out of most bog situations without damage. This feature, combined with its ruggedness, light weight and high ground clearance, made it the ideal car for the farmer.

Many of the Model T Fords were still coming in, semi-dismantled, without bodies, in pine crates from Canada. RH thought the pine timber was too good to waste and commissioned the occasional home furniture to be made from it. He also used the excess Model T running boards as garden edges and foundations for his tennis courts at the family home in Wyrallah Road.

Local towns and shires were growing, and there were considerable improvements in all aspects of life. From these heady days of the Model T sales also escalated the lucrative backyard body building business. Unfortunately, there were continual complaints from owners to Ford in Canada, as to the poor quality of these non-Ford Australian bodies.

Eventually, it caused Ford Canada enough concern to send two representatives, Mr Herbert French and Mr Booth, to Australia in 1923 to report on the customer complaints and the poor service facilities throughout Australia and New Zealand.

The Freedom of Information Act passed in 1982 disclosed the report sent to Ford Canada by these two representatives during their visit to Australia. Following the visit of their representatives, Ford Canada commenced moves to establish their own manufacturing plants in Australia, doing away with all distributors, such as Davies & Fehon, in NSW. Ford purchased an old ex-wool storage building in Geelong, Victoria and work commenced on May 25, 1925 to construct Ford Motor Company’s Australian plant for Model Ts, together with fitting Ford’s own all-steel body with the Ford warrantee.

Sites were chosen in Brisbane and Adelaide for the construction of further assembly plants. The Ford Canadian representative, Herbert French, was given the position of Foundation Managing Director of Ford Australia, which he held for over twenty-five years. Herbert and RH went on to become close associates over the period.

During 1925–1926, a copy of an American idea came in the way of a vehicle finance company, called Traders Finance Corporation Ltd (TFC). Established as a separate arm of Australian Guarantee Corporation (AGC), it was formed to exclusively handle dealers’ vehicle floor plan and retail financing. This new finance structure was called AGC/TFC and was put together by the Ford Motor Company, with assistance from some employees, who invested in it. As a trade off for losing their rights, distributors were given large shareholdings in this new company.

Photo below: 1916-1947, Third Trevan Ford Garage, this facia till 1919.

With a new start, RH purchased an old skating rink building in Molesworth Street, opposite the then Council Chambers building, and began trading again as RH Trevan Motor Engineers.

The old skating rink was an ideal size and had rear access into Carrington Street. The main fault was its wooden floor which, in later years, became oil-soaked and continually needed to be patched, as vehicles or car jacks pushed holes through it. As business progressed, Joe Anderson was employed as a salesman to sell the Model T cars and trucks and later the Irish-built Fordson tractor, which was planned to be released onto the market in Australia in 1918. This tractor became an instant success with farmers but caused mechanics many headaches with its poorly designed gearbox. As RH described to Ford, “ it was a case of shovelling the gears out by the spadeful”. The later models, built in Dagenham in the United Kingdom, proved to be a far superior tractor.

With the outbreak of World War I in 1914, many a farmer and his son enlisted for overseas duty, causing most business activity to slow down until the war’s end in 1918. On return of enlisted men to the farms and industry, Australia was soon on the move again. RH’s belated plans to open a sales and service facility in the neglected Tweed Valley end of the territory were soon implemented. A section of AG Hayes’ coach building works in Prospero Street, South Murwillumbah, was rented and opened for business in 1919, and RH’s brother, Bill, who had come up from the family home in Victoria, was given the opportunity to join the business. He started in the Murwillumbah office and in 1924 took over as manager, when the then manager, Jim Cooper, was transferred to the newly opened Ballina facility.

The next company expansion came with the purchase of land in Casino for another garage outlet in 1922. In the same year, RH floated the firm into a company, RH Trevan Ltd, with shares being issued to Bill Trevan and selected staff. All land and buildings owned by RH, in person, were transferred to the new company in exchange for shares in his name.

From 1918 through to the early 1920s, business was good with sales of Model T Fords buoyant, mainly due to its low price together with the revolutionary semi-automatic transmission that enabled the car to be rocked back and forth out of most bog situations without damage. This feature, combined with its ruggedness, light weight and high ground clearance, made it the ideal car for the farmer.

Many of the Model T Fords were still coming in, semi-dismantled, without bodies, in pine crates from Canada. RH thought the pine timber was too good to waste and commissioned the occasional home furniture to be made from it. He also used the excess Model T running boards as garden edges and foundations for his tennis courts at the family home in Wyrallah Road.

Local towns and shires were growing, and there were considerable improvements in all aspects of life. From these heady days of the Model T sales also escalated the lucrative backyard body building business. Unfortunately, there were continual complaints from owners to Ford in Canada, as to the poor quality of these non-Ford Australian bodies.

Eventually, it caused Ford Canada enough concern to send two representatives, Mr Herbert French and Mr Booth, to Australia in 1923 to report on the customer complaints and the poor service facilities throughout Australia and New Zealand.

The Freedom of Information Act passed in 1982 disclosed the report sent to Ford Canada by these two representatives during their visit to Australia. Following the visit of their representatives, Ford Canada commenced moves to establish their own manufacturing plants in Australia, doing away with all distributors, such as Davies & Fehon, in NSW. Ford purchased an old ex-wool storage building in Geelong, Victoria and work commenced on May 25, 1925 to construct Ford Motor Company’s Australian plant for Model Ts, together with fitting Ford’s own all-steel body with the Ford warrantee.

Sites were chosen in Brisbane and Adelaide for the construction of further assembly plants. The Ford Canadian representative, Herbert French, was given the position of Foundation Managing Director of Ford Australia, which he held for over twenty-five years. Herbert and RH went on to become close associates over the period.

During 1925–1926, a copy of an American idea came in the way of a vehicle finance company, called Traders Finance Corporation Ltd (TFC). Established as a separate arm of Australian Guarantee Corporation (AGC), it was formed to exclusively handle dealers’ vehicle floor plan and retail financing. This new finance structure was called AGC/TFC and was put together by the Ford Motor Company, with assistance from some employees, who invested in it. As a trade off for losing their rights, distributors were given large shareholdings in this new company.

Photo below: 1916-1947, Third Trevan Ford Garage, this facia till 1919.

15 Years Down - 1925

The first Model T Ford sedan-styled body arrived on the North Coast in 1925, in the form of a coupe. Because of the public’s lack of knowledge of this style of body, RH began driving this 2-door coupe to show customers on his daily rounds that even though more costly than a tourer, it was worth the extra money because of the added comfort, especially during inclement weather, due to its wind up windows.

A method the salesmen used to demonstrate the sedan body’s extra strength over the tourer body was by showing the client the strength of a tobacco tin, with the lid closed compared to when the lid was open.

The firm had been now been trading over fifteen years and with it came the knowledge that there is very little profit to be made in selling new motor cars. To overcome this, RH continually stressed that workshop productivity always remains high to ensure that all business overheads were covered by the service department. For the whole of his working life this policy was always adhered to and proved the company’s mainstay and reason why the business survived in a trading climate that saw many dealers fall by the wayside.

By being cost efficient in the workshop, RH was able to create his own fixed-charge, labour booklet that was given to all clients to indicate the cost of every job possible on their Ford car, truck or tractor and also stressed that Trevans could do the repair job on their Ford for less cost and quicker than any competitors. This booklet was available at all Trevan outlets in the Richmond and Tweed Valleys and, to this day, they’re occasionally found in old clients’ family memorabilia.

In a 1925 Northern Star article, it was reported that Ford Australia acknowledged the firm of RH Trevan as the second-oldest established Australian Ford dealer still in operation. The oldest being Tarrants in Maryborough, which at that time was still also owned by the original founders.

Even though Ford Motor Company had been a success story since its inception in 1903, the Model T they introduced in 1908 had changed little and was now becoming old hat, to the point that competitors’ vehicles were now far superior in all aspects.

Throughout the later life of the Model T, RH had been keen to offer his clients a more upmarket car should they wish to trade up. On a low-key basis, RH began to sell the 6-cylinder Hudson and Essex vehicles, which he obtained from the NSW distributors, Dalgety & Co, from their outlet in Woodlark Street, Lismore.

By the mid 1920s, Chevrolet cars from General Motors were now making big inroads into the marketplace where, for many years, Ford had held the major share. By 1926 Ford’s market penetration was now down to eleven and a half per cent. Ford Motor Company unfavourably viewed multi-franchising and, for RH to avoid Ford’s questioning his Hudson and Essex involvement, it was decided to form a separate company to sell and service the Hudson and Essex vehicles, away from the Trevan Molesworth Street garage.

This firm was called Hudex Motors and began trading from the old Dalgety premises in Woodlark Street, with a shareholding consisting of a group of local businessmen and RH. But, to conceal any association, he had his shares registered in his wife’s name, Edith Alicia Trevan. A Trevan salesman, Jack Sharpe’s 1928 day book shows that apart from Ford, the sales of Hudson and Essex vehicles were also an important part of his sales canvassing.

In 1927, Henry Ford decided to cease production of the Model T and retool for an all-new car to be called the Model A. All plants around the world were shut down and, to carry dealers through while the plants were retooling for the new car, Ford planned to make an enormous amount of Model Ts and send them to dealers, who were expected to accept and pay for them immediately.

Those dealers who did not comply generally lost their agencies but those that did and survived this traumatic period came to market a fantastic car that was far superior to many a higher priced competitor. During this earlier turbulent period Ford requested dealers to promote the Fordson tractor heavily. This was possibly done as a means of survival until the new car arrived. To this end, RH actually repainted the front of the garage, emphasising the availability of Fordson tractors in large lettering.

Such was the success of the newly released Model A Ford, that RH severed his association with Hudex Motors to concentrate his full efforts on this new car. Around this time, Hudex Motors employed Sid Pratten, who came from the firm of Canadian Cycle Co. He took on the Dodge and Chrysler franchise when Hudex Motors was dissolved in the early 1930s and this family business, Pratten’s, was to trade in Lismore under the direction of the founder’s son, Jim Pratten and grandson, Mark Pratten for many years.

Coinciding with the release of the new car, Ford began an appraisal of all their dealer outlets. The Queensland Branch General Manager visited RH and on December 3, 1928, reported back to Ford with his findings as follows:

"I stayed with Mr RH Trevan for a matter of four or five days, going thoroughly into conditions appertaining to the territory and the question of increasing his sales staff and also the question of improving his premises at Lismore. Unfortunately, we have to report that the prevailing dry conditions in this particular district of New South Wales are extremely bad and rain is badly needed in order to save large herds of cattle. Many orders have been cancelled on account of the failure of the rain. I visited Ballina with Mr Trevan and found that they had recently moved into new premises which, more or less, can be considered adequate for the present needs of this district.

"The Casino branch I found in very good order indeed with the manager, Mr Harrison, a very enthusiastic worker for the firm and Ford products.

"At Kyogle we found a situation which does not comply with company policy as Trevans is only being represented by a sub-dealer, Mackrell General Machinery. This agent also represents the LHC vehicle product. We also noted the premises were not necessarily suitable for a district the size of Kyogle but Mr Trevan is now making arrangements to either purchase or lease land on which to erect premises, and appoint a branch manager.

"I then visited Murwillumbah branch, together with Mr Trevan and his brother, Will Trevan, the manager. I found conditions here were not so enthusiastic and I have now arranged with Mr Trevan to appoint two or three salesmen in this district and that they thoroughly canvass the area much more than had been done in the past.

"Regarding Lismore, I suggested to Mr Trevan to hold up the re-building of his premises at Lismore until May or June next year. It is felt that his present premises are adequate and that he would be better to concentrate all his time and money on the development of the Ford franchise and increase sales rather than be worried about the building’s image."

It was a good report the representative sent back to Ford Motor Company, but he advised that they would soon be looking at the Kyogle territory, and it was not too long after his return that RH was advised by Ford that the Kyogle territory would be taken from him and given to Messrs GS Mackrell. This was the first implementation of Ford Canada’s policy of controlled dealer territory size, first mentioned in the 1923 French report.

Photo below: 1920s, Ford Trucks having bodies being built at Bangalow Body Builders, aprox. 30 kms from Lismore.

The first Model T Ford sedan-styled body arrived on the North Coast in 1925, in the form of a coupe. Because of the public’s lack of knowledge of this style of body, RH began driving this 2-door coupe to show customers on his daily rounds that even though more costly than a tourer, it was worth the extra money because of the added comfort, especially during inclement weather, due to its wind up windows.

A method the salesmen used to demonstrate the sedan body’s extra strength over the tourer body was by showing the client the strength of a tobacco tin, with the lid closed compared to when the lid was open.

The firm had been now been trading over fifteen years and with it came the knowledge that there is very little profit to be made in selling new motor cars. To overcome this, RH continually stressed that workshop productivity always remains high to ensure that all business overheads were covered by the service department. For the whole of his working life this policy was always adhered to and proved the company’s mainstay and reason why the business survived in a trading climate that saw many dealers fall by the wayside.

By being cost efficient in the workshop, RH was able to create his own fixed-charge, labour booklet that was given to all clients to indicate the cost of every job possible on their Ford car, truck or tractor and also stressed that Trevans could do the repair job on their Ford for less cost and quicker than any competitors. This booklet was available at all Trevan outlets in the Richmond and Tweed Valleys and, to this day, they’re occasionally found in old clients’ family memorabilia.

In a 1925 Northern Star article, it was reported that Ford Australia acknowledged the firm of RH Trevan as the second-oldest established Australian Ford dealer still in operation. The oldest being Tarrants in Maryborough, which at that time was still also owned by the original founders.

Even though Ford Motor Company had been a success story since its inception in 1903, the Model T they introduced in 1908 had changed little and was now becoming old hat, to the point that competitors’ vehicles were now far superior in all aspects.

Throughout the later life of the Model T, RH had been keen to offer his clients a more upmarket car should they wish to trade up. On a low-key basis, RH began to sell the 6-cylinder Hudson and Essex vehicles, which he obtained from the NSW distributors, Dalgety & Co, from their outlet in Woodlark Street, Lismore.

By the mid 1920s, Chevrolet cars from General Motors were now making big inroads into the marketplace where, for many years, Ford had held the major share. By 1926 Ford’s market penetration was now down to eleven and a half per cent. Ford Motor Company unfavourably viewed multi-franchising and, for RH to avoid Ford’s questioning his Hudson and Essex involvement, it was decided to form a separate company to sell and service the Hudson and Essex vehicles, away from the Trevan Molesworth Street garage.

This firm was called Hudex Motors and began trading from the old Dalgety premises in Woodlark Street, with a shareholding consisting of a group of local businessmen and RH. But, to conceal any association, he had his shares registered in his wife’s name, Edith Alicia Trevan. A Trevan salesman, Jack Sharpe’s 1928 day book shows that apart from Ford, the sales of Hudson and Essex vehicles were also an important part of his sales canvassing.

In 1927, Henry Ford decided to cease production of the Model T and retool for an all-new car to be called the Model A. All plants around the world were shut down and, to carry dealers through while the plants were retooling for the new car, Ford planned to make an enormous amount of Model Ts and send them to dealers, who were expected to accept and pay for them immediately.

Those dealers who did not comply generally lost their agencies but those that did and survived this traumatic period came to market a fantastic car that was far superior to many a higher priced competitor. During this earlier turbulent period Ford requested dealers to promote the Fordson tractor heavily. This was possibly done as a means of survival until the new car arrived. To this end, RH actually repainted the front of the garage, emphasising the availability of Fordson tractors in large lettering.

Such was the success of the newly released Model A Ford, that RH severed his association with Hudex Motors to concentrate his full efforts on this new car. Around this time, Hudex Motors employed Sid Pratten, who came from the firm of Canadian Cycle Co. He took on the Dodge and Chrysler franchise when Hudex Motors was dissolved in the early 1930s and this family business, Pratten’s, was to trade in Lismore under the direction of the founder’s son, Jim Pratten and grandson, Mark Pratten for many years.

Coinciding with the release of the new car, Ford began an appraisal of all their dealer outlets. The Queensland Branch General Manager visited RH and on December 3, 1928, reported back to Ford with his findings as follows:

"I stayed with Mr RH Trevan for a matter of four or five days, going thoroughly into conditions appertaining to the territory and the question of increasing his sales staff and also the question of improving his premises at Lismore. Unfortunately, we have to report that the prevailing dry conditions in this particular district of New South Wales are extremely bad and rain is badly needed in order to save large herds of cattle. Many orders have been cancelled on account of the failure of the rain. I visited Ballina with Mr Trevan and found that they had recently moved into new premises which, more or less, can be considered adequate for the present needs of this district.

"The Casino branch I found in very good order indeed with the manager, Mr Harrison, a very enthusiastic worker for the firm and Ford products.

"At Kyogle we found a situation which does not comply with company policy as Trevans is only being represented by a sub-dealer, Mackrell General Machinery. This agent also represents the LHC vehicle product. We also noted the premises were not necessarily suitable for a district the size of Kyogle but Mr Trevan is now making arrangements to either purchase or lease land on which to erect premises, and appoint a branch manager.

"I then visited Murwillumbah branch, together with Mr Trevan and his brother, Will Trevan, the manager. I found conditions here were not so enthusiastic and I have now arranged with Mr Trevan to appoint two or three salesmen in this district and that they thoroughly canvass the area much more than had been done in the past.

"Regarding Lismore, I suggested to Mr Trevan to hold up the re-building of his premises at Lismore until May or June next year. It is felt that his present premises are adequate and that he would be better to concentrate all his time and money on the development of the Ford franchise and increase sales rather than be worried about the building’s image."

It was a good report the representative sent back to Ford Motor Company, but he advised that they would soon be looking at the Kyogle territory, and it was not too long after his return that RH was advised by Ford that the Kyogle territory would be taken from him and given to Messrs GS Mackrell. This was the first implementation of Ford Canada’s policy of controlled dealer territory size, first mentioned in the 1923 French report.

Photo below: 1920s, Ford Trucks having bodies being built at Bangalow Body Builders, aprox. 30 kms from Lismore.

The Great Depression - 1930s

Even though the newly-released Model A Ford was an overnight sensation and sales continued to boom through 1929, times were suddenly to change. In 1930 sales of the 4-cylinder Ford dropped so severely against the GMH 6-cylinder Chevrolet and other 6-cylinder makes, that Ford began to retool for yet another all new motor car with a V8 engine.

With the release of this car in 1932, sales did rise but only temporarily, as the world depression had now begun to take dramatic effect in Australia. This depression virtually brought industry to its knees and people’s spending was down to where only the perceived ‘well off’ were able to buy a new car.

During this difficult period, Trevans, as with most garages, was only employing labour on a casual basis. This saw mechanics arriving, mostly by pushbike, at the garage and waiting with their tool boxes in the hope of getting some employment for the day. Many mechanics who suffered through this period later enjoyed the fruits of full employment and were to see out their working life with the firm. Throughout the depression, Trevans’ electrical department actually expanded and probably kept the business afloat during these difficult times.

With this development, came the move out of the small Magellan Street site to bigger premises at the northern end of Molesworth Street, opposite Wicks Jewellers, with Doug Newton as manager. NRMA appointed Trevans as their local designated electrical repairer and the full-time job of rewinding electrical motors was handled by well-known Miss Elsie Nelson, who attracted work from as far south as Grafton and north to the Tweed and inland to Tenterfield. The sale of batteries, together with their rebuilding, was also a big part of the department’s daily repair work, as many farmers were still relying on batteries to operate appliances such as lighting, radios and such.

The department was also capable of wiring complete households, as records show a letter from an insurance company granting Trevans permission to convert Oakland Castle, near Corak, owned by the prominent Yager family, from gas to electric lighting. New car sales virtually stopped, so to try and cover overheads, the firm turned to converting traded cars into utilities for farm use. Dobbin Sheafer built most of these utility bodies for Trevans and, as it was later seen, the request by Australian farmers for a utility-style vehicle, had Ford Australia in 1934 actually develop the world’s first integral passenger utility body from a sedan base.

Another section of the business that traded through the depression was the trimming department in Carrington Street. Charlie Watson, the manager for many years, went on to start his own business under the name of Watson and Sons, Trimmers. Charlie’s sons, Bruce, Keith and Eric, all worked at some stage of their careers with Trevans and their firm carried out trimming work for the company for many years.

It is noted in the records in 1934 that the organisation, since its inception in 1910, had sold 1,750 new Model T Fords; 485 new Model A, B and V8s; plus 2,000 used cars.

As the depression eased and vehicle sales picked up, Ford released its all new V12 cylinder Lincoln Zephyr sedan in 1937. One of these beautiful cars was sold by RH to his close golfing friend and company solicitor, Jack McIntosh. Both Jack and RH would travel in the Lincoln to important golfing events, such as to the Country Golf Championships in Sydney, with RH doing the driving, so his friend could be fresh for his golfing match on arrival.

Another close friend of RH, was farmer and inventor, Bill York from Swan Bay. One of his notable inventions was a rotary hoe that would work successfully behind the Fordson tractor. This was accomplished by Bill redesigning the gearbox ratio. He later took his design together with another non-patented invention to America and spoke to Henry Ford about them. Even though his ideas fell on deaf ears, much to Bill’s surprise, he later received a gift of a new plough for his tractor from the Ford Motor Company in the USA. The other non-patented invention was a music record changer, which was copied in the USA and came to be used worldwide in the ‘Jukebox’.

When he purchased his first tractor from RH, the story was often told how Bill York drove the tractor, on its steel plated wheels, from Byron Bay wharf to Swan Bay. The trip took over forty-eight hours and, to guide him by night, he used a lantern tied to the front of the tractor.

In 1937 Ford released its first full, all-steel turret on its V8 sedans and with it came a much safer and stronger bodied motorcar. In the same year, the companies, on accountants’ advice, re structured RH Trevan Ltd to RH Trevan Pty Ltd, mainly because of a new Government Tax Legislation.

Photo below: 1939, Spare Parts Manager, George Jackson at Lismore branch.

Even though the newly-released Model A Ford was an overnight sensation and sales continued to boom through 1929, times were suddenly to change. In 1930 sales of the 4-cylinder Ford dropped so severely against the GMH 6-cylinder Chevrolet and other 6-cylinder makes, that Ford began to retool for yet another all new motor car with a V8 engine.

With the release of this car in 1932, sales did rise but only temporarily, as the world depression had now begun to take dramatic effect in Australia. This depression virtually brought industry to its knees and people’s spending was down to where only the perceived ‘well off’ were able to buy a new car.

During this difficult period, Trevans, as with most garages, was only employing labour on a casual basis. This saw mechanics arriving, mostly by pushbike, at the garage and waiting with their tool boxes in the hope of getting some employment for the day. Many mechanics who suffered through this period later enjoyed the fruits of full employment and were to see out their working life with the firm. Throughout the depression, Trevans’ electrical department actually expanded and probably kept the business afloat during these difficult times.

With this development, came the move out of the small Magellan Street site to bigger premises at the northern end of Molesworth Street, opposite Wicks Jewellers, with Doug Newton as manager. NRMA appointed Trevans as their local designated electrical repairer and the full-time job of rewinding electrical motors was handled by well-known Miss Elsie Nelson, who attracted work from as far south as Grafton and north to the Tweed and inland to Tenterfield. The sale of batteries, together with their rebuilding, was also a big part of the department’s daily repair work, as many farmers were still relying on batteries to operate appliances such as lighting, radios and such.

The department was also capable of wiring complete households, as records show a letter from an insurance company granting Trevans permission to convert Oakland Castle, near Corak, owned by the prominent Yager family, from gas to electric lighting. New car sales virtually stopped, so to try and cover overheads, the firm turned to converting traded cars into utilities for farm use. Dobbin Sheafer built most of these utility bodies for Trevans and, as it was later seen, the request by Australian farmers for a utility-style vehicle, had Ford Australia in 1934 actually develop the world’s first integral passenger utility body from a sedan base.

Another section of the business that traded through the depression was the trimming department in Carrington Street. Charlie Watson, the manager for many years, went on to start his own business under the name of Watson and Sons, Trimmers. Charlie’s sons, Bruce, Keith and Eric, all worked at some stage of their careers with Trevans and their firm carried out trimming work for the company for many years.

It is noted in the records in 1934 that the organisation, since its inception in 1910, had sold 1,750 new Model T Fords; 485 new Model A, B and V8s; plus 2,000 used cars.

As the depression eased and vehicle sales picked up, Ford released its all new V12 cylinder Lincoln Zephyr sedan in 1937. One of these beautiful cars was sold by RH to his close golfing friend and company solicitor, Jack McIntosh. Both Jack and RH would travel in the Lincoln to important golfing events, such as to the Country Golf Championships in Sydney, with RH doing the driving, so his friend could be fresh for his golfing match on arrival.

Another close friend of RH, was farmer and inventor, Bill York from Swan Bay. One of his notable inventions was a rotary hoe that would work successfully behind the Fordson tractor. This was accomplished by Bill redesigning the gearbox ratio. He later took his design together with another non-patented invention to America and spoke to Henry Ford about them. Even though his ideas fell on deaf ears, much to Bill’s surprise, he later received a gift of a new plough for his tractor from the Ford Motor Company in the USA. The other non-patented invention was a music record changer, which was copied in the USA and came to be used worldwide in the ‘Jukebox’.

When he purchased his first tractor from RH, the story was often told how Bill York drove the tractor, on its steel plated wheels, from Byron Bay wharf to Swan Bay. The trip took over forty-eight hours and, to guide him by night, he used a lantern tied to the front of the tractor.

In 1937 Ford released its first full, all-steel turret on its V8 sedans and with it came a much safer and stronger bodied motorcar. In the same year, the companies, on accountants’ advice, re structured RH Trevan Ltd to RH Trevan Pty Ltd, mainly because of a new Government Tax Legislation.

Photo below: 1939, Spare Parts Manager, George Jackson at Lismore branch.

Employment Relations - 1930s

During the mid-1930s, staff picnics at various beaches were big social events with approximately one hundred and fifty staff and families from all branches attending. These combined picnics were regularly held at Byron Bay or Lennox Head, and were reported at length in The Northern Star paper. After morning tea there was a program of sports until lunch, whereupon RH, as the Managing Director, took the opportunity to make a speech to welcome the guests and expressed his pleasure in meeting the families of his staff from all branches.

After lunch, the sports program would continue with old fashioned contests such as foot races; three-legged and sack races; Old Buffers and flag races; high jumps, hop, step and jump, and tug-o’-war contests. In each of these competitions there were events for ladies as well as boys and girls. Prize money was made available by RH himself and other business associates.

One report from this period told of a combined motor dealers’ picnic at Broken Head, involving the two motor houses of Robinson’s, the GMH motor dealer, and Trevans, which had been situated next door to each other in Molesworth Street for many years. This great day was attended by more than two hundred staff from both firms with their families, together with an ambulance officer from Lismore to hand out sunburn lotion, so that everyone could enjoy the surf and beach activities. At afternoon teatime, both RH and Bill Robinson, made speeches about their history together with friendly banter about how Robinson’s had supported Trevans for many years. This was because the old Trevan building was supposedly leaning on the younger Robinson building, which was stopping it from falling over.

RH’s first encounters with Bill Robinson had been nearly twenty years earlier when RH sold him a car and also taught him to drive it. While RH had gone on to found a highly successful Ford franchise business, Bill Robinson had taken a parallel path to achieve similar heights with the General Motors franchise. In 1936, RH mentioned at a staff picnic the desirability in the future to build new brick premises on the present site in Molesworth Street. This rebuilding situation had been held back since 1928 on Ford Motor Company’s recommendations.

At a later picnic, RH took the opportunity to explain plans for a new facility, on land that had now been purchased in Keen Street, next to a corner service station that was large enough to house the sales and service departments all under one roof.

By mid 1936, the operation was possibly the biggest employer on the Far North Coast, with forty-five on the staff and an annual wages bill in excess of ten thousand pounds ($20,000). At that time, amongst the longest serving members of the staff were Noel Thompson (Lismore), fifteen years; Cecil Partridge (Murwillumbah), twenty years; Roy Squelch (Ballina), thirteen years and H Irvine (Casino), thirteen years. Will Trevan, the Murwillumbah Manager, had been with RH for fifteen years, as had PW Harrison, the Lismore Manager, and Miss Stewart, the firm’s secretary for thirteen years.

It had always been company policy to employ local men and youths and RH always made sure that his mechanics and department foremen were sent off to the Ford Motor Company service schools, to ensure they had the knowledge they needed to provide the expert servicing that he always prided the firm on being able to offer.

Photo below: 1930s, Lismore staff.

During the mid-1930s, staff picnics at various beaches were big social events with approximately one hundred and fifty staff and families from all branches attending. These combined picnics were regularly held at Byron Bay or Lennox Head, and were reported at length in The Northern Star paper. After morning tea there was a program of sports until lunch, whereupon RH, as the Managing Director, took the opportunity to make a speech to welcome the guests and expressed his pleasure in meeting the families of his staff from all branches.

After lunch, the sports program would continue with old fashioned contests such as foot races; three-legged and sack races; Old Buffers and flag races; high jumps, hop, step and jump, and tug-o’-war contests. In each of these competitions there were events for ladies as well as boys and girls. Prize money was made available by RH himself and other business associates.

One report from this period told of a combined motor dealers’ picnic at Broken Head, involving the two motor houses of Robinson’s, the GMH motor dealer, and Trevans, which had been situated next door to each other in Molesworth Street for many years. This great day was attended by more than two hundred staff from both firms with their families, together with an ambulance officer from Lismore to hand out sunburn lotion, so that everyone could enjoy the surf and beach activities. At afternoon teatime, both RH and Bill Robinson, made speeches about their history together with friendly banter about how Robinson’s had supported Trevans for many years. This was because the old Trevan building was supposedly leaning on the younger Robinson building, which was stopping it from falling over.

RH’s first encounters with Bill Robinson had been nearly twenty years earlier when RH sold him a car and also taught him to drive it. While RH had gone on to found a highly successful Ford franchise business, Bill Robinson had taken a parallel path to achieve similar heights with the General Motors franchise. In 1936, RH mentioned at a staff picnic the desirability in the future to build new brick premises on the present site in Molesworth Street. This rebuilding situation had been held back since 1928 on Ford Motor Company’s recommendations.

At a later picnic, RH took the opportunity to explain plans for a new facility, on land that had now been purchased in Keen Street, next to a corner service station that was large enough to house the sales and service departments all under one roof.

By mid 1936, the operation was possibly the biggest employer on the Far North Coast, with forty-five on the staff and an annual wages bill in excess of ten thousand pounds ($20,000). At that time, amongst the longest serving members of the staff were Noel Thompson (Lismore), fifteen years; Cecil Partridge (Murwillumbah), twenty years; Roy Squelch (Ballina), thirteen years and H Irvine (Casino), thirteen years. Will Trevan, the Murwillumbah Manager, had been with RH for fifteen years, as had PW Harrison, the Lismore Manager, and Miss Stewart, the firm’s secretary for thirteen years.

It had always been company policy to employ local men and youths and RH always made sure that his mechanics and department foremen were sent off to the Ford Motor Company service schools, to ensure they had the knowledge they needed to provide the expert servicing that he always prided the firm on being able to offer.

Photo below: 1930s, Lismore staff.

The Service Station, Corner Keen and Conway Street, Lismore

In 1937 RH purchased a half-share in the previously mentioned, newly-built service station, on the corner of Keen and Conway Streets, from CJ Harvey. Later that year, it became fully-owned by Trevans and on call twenty-four hours a day, with an employee sleeping on the premises. An outside bell was used to awaken the attendant, should service be required after hours. The attendant on duty was allowed an hour’s break for breakfast and tea, and Friday night off for shopping purposes, with the then five and a half day working week being forty-four hours. It was often said that this was the testing grounds for many a Trevan employee.

With business times still not being easy, RH would personally run the service station as much as possible on Sunday mornings and, as most of the pumps were still hand-operated, it was quite common to see him pumping fuel to a line up of motor cars that stretched well up Keen Street.

Petrol sales always ran between 6,000 to 10,000 gallons per month (27,276 to 45,460 litres) and the greasing of cars every 500 miles (800 kilometres), with oil changes at 1,000 miles (1,600 kilometres), was a big part of Saturday morning trade, especially with commercial travellers who only had their cars available at weekends for service. RH once employed a young lass to help him with the serving of petrol and oil on Sundays. This turned out a short-lived experiment when it was found that when the drivers would ask for fuel and oil, she had a habit of putting both in the petrol tanks, much to the dismay of the client.

In 1938 an all-new piece of equipment called the Lincoln Electric Welder was purchased by the firm. This unit, together with another at Flynn’s Foundry, were to be the only two of their type for many years in the Lismore district. It was a great money maker for the firm, especially with the repairing of cracks in Ford chassis' spring-mounted, cross members, which broke regularly because of the poor local road conditions. Trevans installed Lismore’s first wheel alignment machine, called a Bean Aligner, which also was a great success for many years.

The next implementation of Ford Canada’s dealer size agenda began to impact, in 1938, onto the Trevan business. As much as RH and his brother, Bill, tried to keep the Tweed Valley territory, it was destined to be the next territory to be taken from them. With the eventual loss of the Murwillumbah branch, all vehicles were bought back to Lismore, where the Sales Manager, Cec Pestall, directed the saleable used vehicles to the rented sales building, opposite the Presbyterian Church in Keen Street and all others to the Trevan wrecking yard , the site of the present workshop, for dismantling as spare parts.

It is noted in the company’s minute books that discussion took place as to the possible expansion of the car sales department and the running of it as a totally separate operation, with its own staff on a separate wage index. This did eventually happen but only at cessation of war in 1946 when it became known as Trevan Car Sales Pty Ltd.

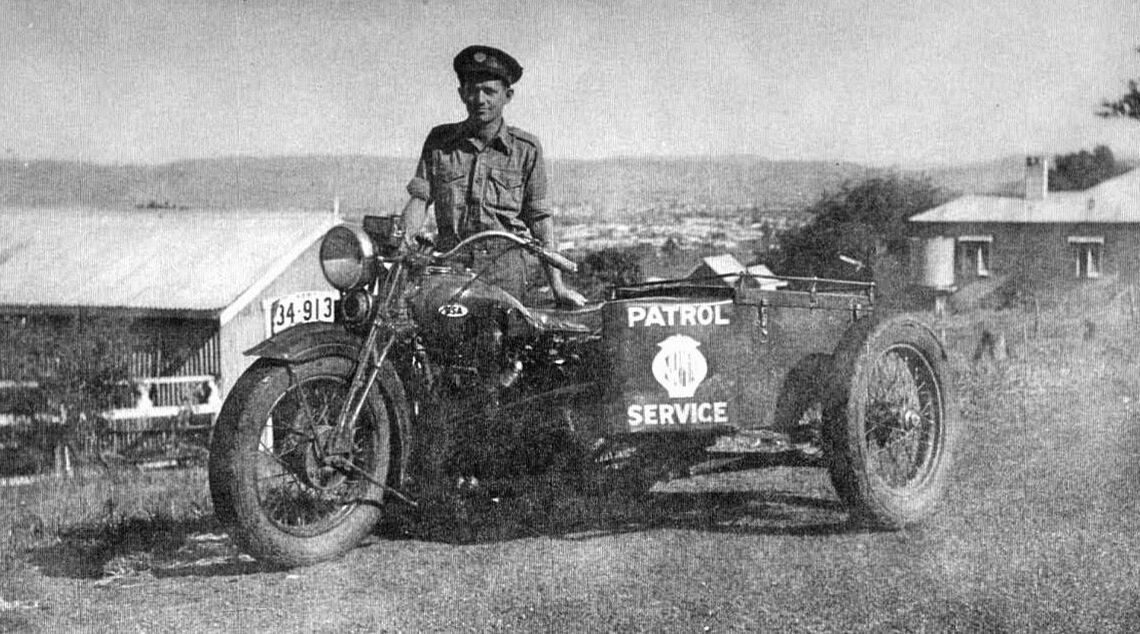

Photo below: 1936, Trevans Ford Ballina Branch, started first with NRMA. Gordon Smith on bike through WW2.

In 1937 RH purchased a half-share in the previously mentioned, newly-built service station, on the corner of Keen and Conway Streets, from CJ Harvey. Later that year, it became fully-owned by Trevans and on call twenty-four hours a day, with an employee sleeping on the premises. An outside bell was used to awaken the attendant, should service be required after hours. The attendant on duty was allowed an hour’s break for breakfast and tea, and Friday night off for shopping purposes, with the then five and a half day working week being forty-four hours. It was often said that this was the testing grounds for many a Trevan employee.

With business times still not being easy, RH would personally run the service station as much as possible on Sunday mornings and, as most of the pumps were still hand-operated, it was quite common to see him pumping fuel to a line up of motor cars that stretched well up Keen Street.

Petrol sales always ran between 6,000 to 10,000 gallons per month (27,276 to 45,460 litres) and the greasing of cars every 500 miles (800 kilometres), with oil changes at 1,000 miles (1,600 kilometres), was a big part of Saturday morning trade, especially with commercial travellers who only had their cars available at weekends for service. RH once employed a young lass to help him with the serving of petrol and oil on Sundays. This turned out a short-lived experiment when it was found that when the drivers would ask for fuel and oil, she had a habit of putting both in the petrol tanks, much to the dismay of the client.

In 1938 an all-new piece of equipment called the Lincoln Electric Welder was purchased by the firm. This unit, together with another at Flynn’s Foundry, were to be the only two of their type for many years in the Lismore district. It was a great money maker for the firm, especially with the repairing of cracks in Ford chassis' spring-mounted, cross members, which broke regularly because of the poor local road conditions. Trevans installed Lismore’s first wheel alignment machine, called a Bean Aligner, which also was a great success for many years.

The next implementation of Ford Canada’s dealer size agenda began to impact, in 1938, onto the Trevan business. As much as RH and his brother, Bill, tried to keep the Tweed Valley territory, it was destined to be the next territory to be taken from them. With the eventual loss of the Murwillumbah branch, all vehicles were bought back to Lismore, where the Sales Manager, Cec Pestall, directed the saleable used vehicles to the rented sales building, opposite the Presbyterian Church in Keen Street and all others to the Trevan wrecking yard , the site of the present workshop, for dismantling as spare parts.

It is noted in the company’s minute books that discussion took place as to the possible expansion of the car sales department and the running of it as a totally separate operation, with its own staff on a separate wage index. This did eventually happen but only at cessation of war in 1946 when it became known as Trevan Car Sales Pty Ltd.

Photo below: 1936, Trevans Ford Ballina Branch, started first with NRMA. Gordon Smith on bike through WW2.

The War Years, 1939 -1945

Australia was nearly fully recovered from the recession and local dairy products were selling well throughout Australia and overseas. The future looked prosperous for the nine hundred local dairy farmers and trade for the district. Suddenly, in 1938, any future plans for business expansion were soon to be curtailed as Europe, and eventually Australia, was drawn into World War II.

Until now the Trevan Company had survived through the World War I downturn and the world recession, plus many major and minor floods. Along with droughts and some serious managerial situations involving some misappropriation of funds court case actions, all of which must have tested RH and the company to the limit.

By 1939, staff had started to be called up for war service. Fortunately for the Trevan operation, it was able to keep trading because of its government classification as an essential industry. This allowed sufficient staff to be excluded from call-up to maintain vehicles belonging to police and army, together with vehicles used for building of the Evans Head aerodrome and the local army battalion fleet of Ford-equipped Bren Gun carriers, which were mainly based in the Nimbin area.

With the advent of World War II came petrol rationing and restrictions on new spare parts, only available on completion of many government forms, and then only for motorcars and trucks classified as an essential service vehicle. Other vehicles received a lower classification that only had parts released to them after a long waiting period. Second-hand spare parts, especially tyres and batteries, demanded premium prices, which made the Trevan wrecking yard a popular place for people trying to keep their cars going.

Motor vehicles of the time were none too reliable compared to today’s cars. Engine lives were 40,000 to 50,000 miles; spring shackles 15,000, plus the all too common Ford problem, of the breaking of the chassis cross members, axles and springs, saw many a good car go to the war scrap metal drive. To try and keep vehicles roadworthy, mechanics of this period became experts in scavenging, fabricating or substituting parts from different makes of motor vehicles. Rebuilding unserviceable batteries by dismantling and replacing the lead plates was an everyday practice by the Trevan electrical department.

Another job done by the electrical department was the adding of acid and charging the large batteries that were fitted into the locally built reconnaissance boats, made for the USA Navy by the AK Barnes Joinery Works in Wyrallah Road, Lismore. These batteries came in without acid from the Government Supplies Department, and it was staff member Roy Cuskelly’s job in the electrical department to fill them with acid, then charge, and this was repeated before they were fitted into the boats.

During this war period, petrol rationing had the average motorist receiving four to eight gallons of petrol per month, depending on the size and use of their vehicle. This was controlled by the issuing of government petrol tickets, soon resulting in a black market that eventually became a day-to-day occurrence, with almost everyone needing to drive their car any distance.

During the early part of the war RH placed an article in The Northern Star for the local Motor Traders’ Association, which said that even though a major war was on, the association wished motorists to contribute to the war effort by buying a new car or having the necessary repairs done to their vehicles, so that more taxes could go to the government to assist with the war effort.

As the war progressed, the only new vehicles to be manufactured in Australia were trucks, which mostly went to essential industries. Records show that the Trevan Company received only two orders for new vehicles throughout the period and only those in the latter war years.

In 1939, RH’s close friend and the business’ solicitor, Jack McIntosh, purchased another 12-cylinder Lincoln Zephyr but, with the introduction of fuel rationing, he traded the vehicle back on a smaller Ford V8. Years later, he requested the V8 be repainted but, as he could not do without his car from Monday to Friday, Trevans’ painter, ‘Pop’ Pixton, brush painted the car at Jack’s home in Uralba Street over one weekend. Such was Pop’s expertise, his jobs were indistinguishable from spray painting. He was also an expert with scrolls, a common practice used on horse drawn vehicles as well as trucks and vans at the time. Pop’s trademark in the paint shop was an enormous scroll on the wall facing Carrington Street. His son-in-law, Kel Callaghan, followed him in the trade, working for the Trevan Company for many years.

With the escalation of the war, all future building plans for the firm were put on hold. In 1939, RH wrote to the War Minister of Supply in Canberra, informing them that he had available 32,340 square feet of land in Keen Street, the site of the present premises, which would make an ideal site for an ammunition factory. Naturally, in RH’s mind was the availability of an instant workshop at the cessation of the war. Unfortunately, this ammunition factory never eventuated.

Throughout the war period, there was so little fuel available that the service station added a facility to fill vehicles converted to run on town gas. These vehicles, buses, trucks and some cars had a large storage bag made from a very sticky airtight material strapped inside a piped frame that was built on top of the entire length of the vehicle, about 1.2 metres (4’) high.

Another device used to fuel vehicles in wartime was called a gas producer, which was generally fitted to the rear of the vehicle. These units burnt coke-wood that had been burnt in a special process without oxygen. Trevans always carried up to a dozen of these units in stock and specialised in their fitting, which was mostly done by Hercules ‘Herk’ Walker, who also carried out their cleaning and re-filling in the old paint shop facing Carrington Street. The company always held for sale many bags of this coke in the same building and, when the operation of cleaning and re-coking these units was in progress, all that could be seen through the coke haze were Herk’s two white eyes—so much for today’s work cover, but he lived to great age.

To clean or refill these units, the lid on top was opened to allow fresh air to enter the hopper. In a short time there would be a small explosion that cleared the unit of unburnt gas. To hurry the action along the dangerous practice of throwing a lighted match into the hopper was used. RH continually preached the precaution of keeping well back when doing this exercise, but one day when demonstrating to staff, the explosion burnt all the hair from his arms and forehead. Staff member, Brian McSweeney, tells how the firm’s 1934 Ford V8 tow truck was fitted with one of these heavy gas producers that, unfortunately, had to be fitted to the side of the vehicle. Once, when rounding a corner near Rosebank, the unit tipped the truck over onto its side but fortunately Roy was able to put out the gas producer’s fire before the vehicle burnt out.

Photo below: 1950's, Lismore Ford Ambulances, Trevan’s serviced their continual updated fleets into the late 1970’s.

Australia was nearly fully recovered from the recession and local dairy products were selling well throughout Australia and overseas. The future looked prosperous for the nine hundred local dairy farmers and trade for the district. Suddenly, in 1938, any future plans for business expansion were soon to be curtailed as Europe, and eventually Australia, was drawn into World War II.

Until now the Trevan Company had survived through the World War I downturn and the world recession, plus many major and minor floods. Along with droughts and some serious managerial situations involving some misappropriation of funds court case actions, all of which must have tested RH and the company to the limit.

By 1939, staff had started to be called up for war service. Fortunately for the Trevan operation, it was able to keep trading because of its government classification as an essential industry. This allowed sufficient staff to be excluded from call-up to maintain vehicles belonging to police and army, together with vehicles used for building of the Evans Head aerodrome and the local army battalion fleet of Ford-equipped Bren Gun carriers, which were mainly based in the Nimbin area.

With the advent of World War II came petrol rationing and restrictions on new spare parts, only available on completion of many government forms, and then only for motorcars and trucks classified as an essential service vehicle. Other vehicles received a lower classification that only had parts released to them after a long waiting period. Second-hand spare parts, especially tyres and batteries, demanded premium prices, which made the Trevan wrecking yard a popular place for people trying to keep their cars going.

Motor vehicles of the time were none too reliable compared to today’s cars. Engine lives were 40,000 to 50,000 miles; spring shackles 15,000, plus the all too common Ford problem, of the breaking of the chassis cross members, axles and springs, saw many a good car go to the war scrap metal drive. To try and keep vehicles roadworthy, mechanics of this period became experts in scavenging, fabricating or substituting parts from different makes of motor vehicles. Rebuilding unserviceable batteries by dismantling and replacing the lead plates was an everyday practice by the Trevan electrical department.

Another job done by the electrical department was the adding of acid and charging the large batteries that were fitted into the locally built reconnaissance boats, made for the USA Navy by the AK Barnes Joinery Works in Wyrallah Road, Lismore. These batteries came in without acid from the Government Supplies Department, and it was staff member Roy Cuskelly’s job in the electrical department to fill them with acid, then charge, and this was repeated before they were fitted into the boats.

During this war period, petrol rationing had the average motorist receiving four to eight gallons of petrol per month, depending on the size and use of their vehicle. This was controlled by the issuing of government petrol tickets, soon resulting in a black market that eventually became a day-to-day occurrence, with almost everyone needing to drive their car any distance.

During the early part of the war RH placed an article in The Northern Star for the local Motor Traders’ Association, which said that even though a major war was on, the association wished motorists to contribute to the war effort by buying a new car or having the necessary repairs done to their vehicles, so that more taxes could go to the government to assist with the war effort.

As the war progressed, the only new vehicles to be manufactured in Australia were trucks, which mostly went to essential industries. Records show that the Trevan Company received only two orders for new vehicles throughout the period and only those in the latter war years.

In 1939, RH’s close friend and the business’ solicitor, Jack McIntosh, purchased another 12-cylinder Lincoln Zephyr but, with the introduction of fuel rationing, he traded the vehicle back on a smaller Ford V8. Years later, he requested the V8 be repainted but, as he could not do without his car from Monday to Friday, Trevans’ painter, ‘Pop’ Pixton, brush painted the car at Jack’s home in Uralba Street over one weekend. Such was Pop’s expertise, his jobs were indistinguishable from spray painting. He was also an expert with scrolls, a common practice used on horse drawn vehicles as well as trucks and vans at the time. Pop’s trademark in the paint shop was an enormous scroll on the wall facing Carrington Street. His son-in-law, Kel Callaghan, followed him in the trade, working for the Trevan Company for many years.

With the escalation of the war, all future building plans for the firm were put on hold. In 1939, RH wrote to the War Minister of Supply in Canberra, informing them that he had available 32,340 square feet of land in Keen Street, the site of the present premises, which would make an ideal site for an ammunition factory. Naturally, in RH’s mind was the availability of an instant workshop at the cessation of the war. Unfortunately, this ammunition factory never eventuated.

Throughout the war period, there was so little fuel available that the service station added a facility to fill vehicles converted to run on town gas. These vehicles, buses, trucks and some cars had a large storage bag made from a very sticky airtight material strapped inside a piped frame that was built on top of the entire length of the vehicle, about 1.2 metres (4’) high.

Another device used to fuel vehicles in wartime was called a gas producer, which was generally fitted to the rear of the vehicle. These units burnt coke-wood that had been burnt in a special process without oxygen. Trevans always carried up to a dozen of these units in stock and specialised in their fitting, which was mostly done by Hercules ‘Herk’ Walker, who also carried out their cleaning and re-filling in the old paint shop facing Carrington Street. The company always held for sale many bags of this coke in the same building and, when the operation of cleaning and re-coking these units was in progress, all that could be seen through the coke haze were Herk’s two white eyes—so much for today’s work cover, but he lived to great age.

To clean or refill these units, the lid on top was opened to allow fresh air to enter the hopper. In a short time there would be a small explosion that cleared the unit of unburnt gas. To hurry the action along the dangerous practice of throwing a lighted match into the hopper was used. RH continually preached the precaution of keeping well back when doing this exercise, but one day when demonstrating to staff, the explosion burnt all the hair from his arms and forehead. Staff member, Brian McSweeney, tells how the firm’s 1934 Ford V8 tow truck was fitted with one of these heavy gas producers that, unfortunately, had to be fitted to the side of the vehicle. Once, when rounding a corner near Rosebank, the unit tipped the truck over onto its side but fortunately Roy was able to put out the gas producer’s fire before the vehicle burnt out.

Photo below: 1950's, Lismore Ford Ambulances, Trevan’s serviced their continual updated fleets into the late 1970’s.

Post War Problems and floods

No sooner were celebrations of the war's end over in 1945, that yet another adversity hit. A massive 12.7 metre flood struck, and with it came enormous losses for the district and Trevans. The water rose so rapidly that few staff were able to get to the shop to assist in shifting stock and customers’ cars.

All the firm’s and customers’ vehicles suffered considerable water damage, together with most of the new spare parts, administration records, and historic photographs all being lost. The job of cleaning up became a mammoth task as the town water supply, as well as the power supply, were both out for a considerable time. Local businesses, and the district in general, took many years to recover from this disastrous flood and the Trevan Company virtually closed it's doors to most outside work for nearly three months while the equipment and clients’ cars were restored to pre-flood condition at the firm’s expense.

Any cars that had been covered with flood water were continually plagued with electrical problems due to the fabric-coated wiring of the time. New wiring was not available, as vehicle parts’ manufacturers had not yet fully returned back to normal supply after the war. To add to the difficulty, most batteries that had been covered by flood water, soon failed even though they had been drained and refilled with acid. The difficult task of removing water from the petrol tanks involved drilling out the rust in drain bungs. One vehicle, owned by Joe Habib, was nearly burnt out by fire during this process, when the fuel exploded after it ran down into the electric drill being used to remove the petrol tank bung.

With the war over and demand picking up, the government required new car buyers to fill in numerous forms and, at government discretion, vehicles were then allocated out on a priority basis system. Naturally this led to black market trading and generally persons with ready money only seemed to be the ones to receive new vehicle allocations. Most vehicle manufacturers were only able to supply revamped pre-war models, as in Ford’s case, and the English imports still used their old transverse springs design and even mechanically-operated brakes on the cars.

Because of the shortage of new and used vehicles, prices of second-hand vehicles were pegged by the government. This control also started the black market selling of used cars by private owners, and left a shortage of traded cars for sale by dealers. To supplement the shortage of cars, RH resorted to getting any agency that had items that the firm could sell, such as motor mowers, boat engines, motor scooters and milking machines. Also any ex-Army vehicles, the purchasing of which took place at army disposal depots in Brisbane and at Wallangarah (via Tenterfield).

To assist with the rectification and transporting of these vehicles, RH employed an ex-army mechanic, Wally Bulmer, who was extremely helpful with the particular mechanical problems associated with these types of vehicles before they were driven to Lismore. After these vehicles were convoyed to Lismore, they were stored at the rear of the Trevan family home in Wyrallah Road, making it look like an army depot for many years. One of these four-wheel drive Blitz trucks had only five miles (nine kilometres) on the speedometer and was selected to become the company’s tow truck. It worked faithfully for forty years, until retired in 1987.